Captrain Polska

ZIELONI. INNOWACYJNI. ZAWSZE PATRZĄCY W PRZYSZŁOŚĆ.

Witamy na stronie Captrain Polska, niezależnego przewoźnika kolejowego operującego na terenie całej Polski! Kilkadziesiąt lokomotyw elektrycznych i spalinowych oraz 2-procentowy udział w polskim rynku kolejowym gwarantuje nam miejsce wśród spółek mogących zaoferować profesjonalną i kompleksową usługę transportową. Dzięki naszemu niemal 15-letniemu doświadczeniu oraz przynależności do międzynarodowej grupy kapitałowej, zapewniamy naszym Klientom dostęp do międzynarodowych standardów usług świadczonych na terenie całej Europy, zachowując jednocześnie indywidualne i partnerskie podejście do każdego Klienta. Więcej

Co nas napędza? Twoja satysfakcja.

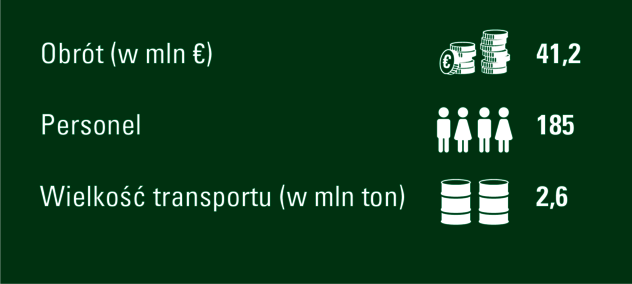

Z udziałem 185 pracowników, 36 lokomotyw i 122 wagonów towarowych, Captrain Polska przetransportował w 2024 r ponad 2,6 miliony ton towarów i 851 miliony NTK, osiągając obrót w wysokości 41,2 milionów euro.

Kluczowe dane spółki 2024